Catalysts that enable selective and efficient conversion of plastics, composites, and formulations into high-value functional chemical building blocks are essential for these complex challenges.

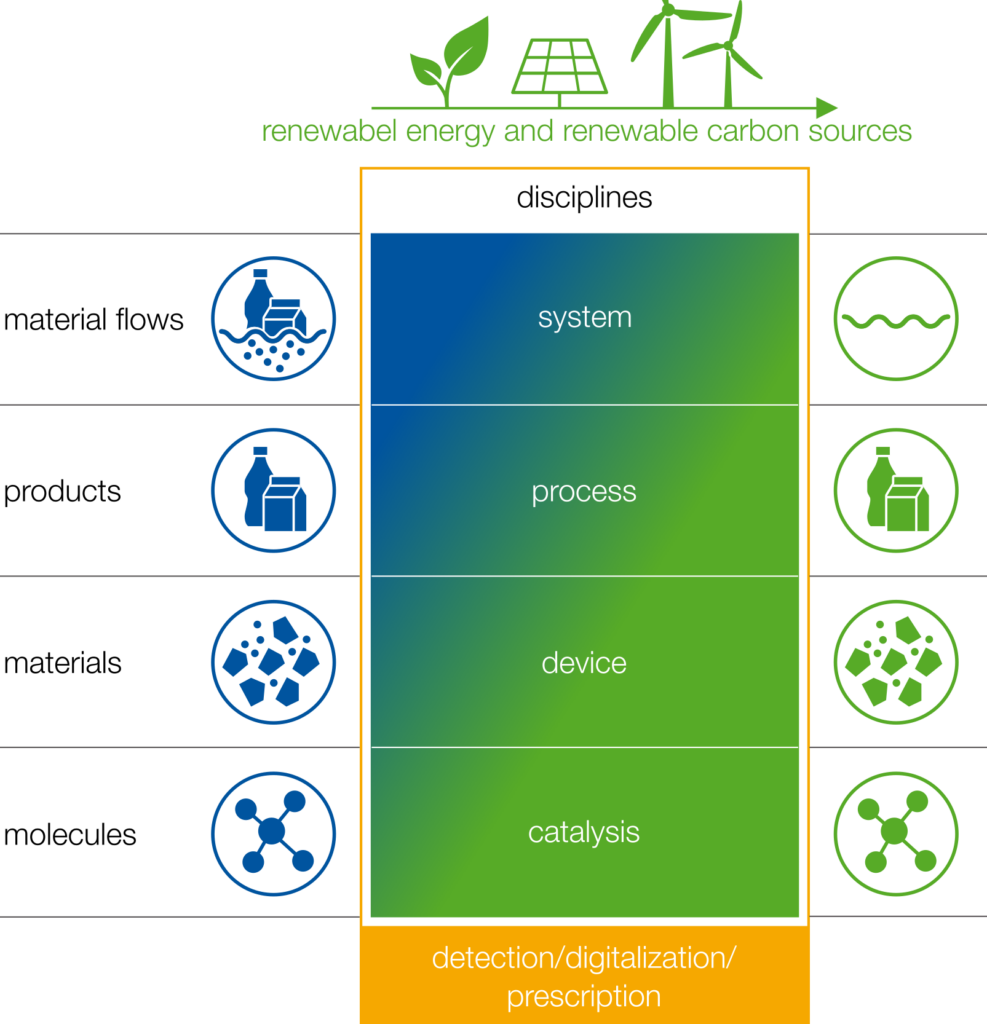

On the size scale from molecule to material and to product, catalaix spans the range of disciplines involved, from catalysis to device and process to the system of global material cycles.

The scientific-technological objective of catalaix is the holistic development and optimization of Open-Loop recycling technologies for the valorization of complex waste material streams and mixed fractions over these size scales. With these technologies, the integration of the value-added paths into the multidimensional circular economy can be achieved.

catalaix brings together the disciplines that are necessary for implementing the fields of action presented into a tailor-made interdisciplinary consortium, which will together iteratively advance the holistic optimization of technologies for the circular economy system. To accelerate the innovation cycles for the required Open-Loop recycling technologies,

Thus, it will be possible to sort material flows more efficiently, to comprehensively analyze reaction and catalyst systems and to identify systemic challenges (detection), to establish data-driven models in combination with automation and high-throughput testing (digitalization) and to define development targets of the different size scales (prescription).

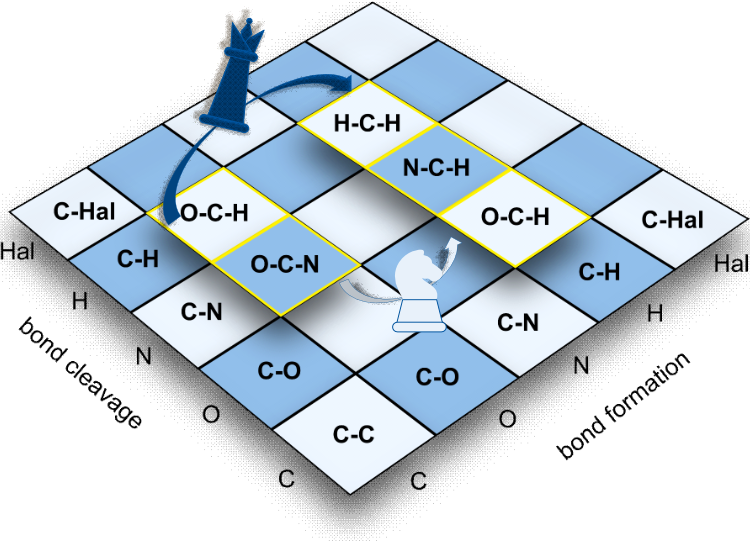

This approach can be illustrated as a chessboard, in which the different catalysts represent the respective chess figures on the synthesis chessboard.

The chemical tansformations will not be considered in isolation in catalaix.

Instead, an integrated reaction, reactor, and process design will be targeted

already in the early development phase. With this interdisciplinary collaboration, the maximum potential of the processes can be effectively developed, and rapid translation of the technologies can be achieved in a targeted manner, focussing on complexity of inhomogeneous plastic input streams, reaction media and separation.

While the catalytic conversion of individual polymer classes forms the basis, innovative strategies for dealing with mixed fractions and various real plastic sources must be developed. Particularly noteworthy here is the handling of microplastics from the environment, which must be collected in aqueous environments and subsequently concentrated. For the conversion of this material stream, catalaix will focus on bio-catalysis and electrocatalysis methods.

The level of system analysis and assessment interlinks chemical, biotechnological and process engineering research in catalaix.

Here, detection is used to identify the challenges of the circular economy system and the waste streams generated as input to the catalaix research world. The ex- ante/accompanying sustainability assessment of the approaches developed in catalaix serves as a potential analysis accompanying the research. Furthermore, integration strategies into the Open-Loop recycling system will be developed.